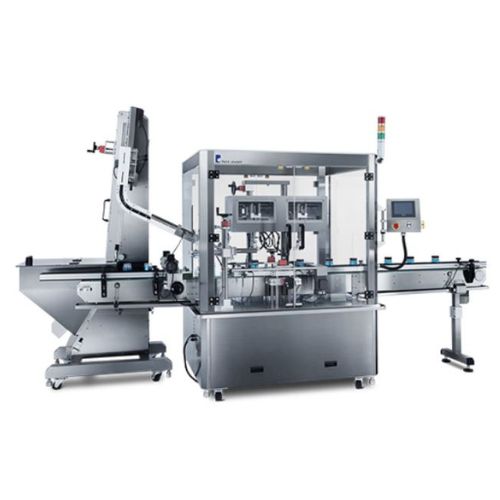

CCP-131 Continuous Pick and Place Capping Machine

A continuous motion, pick and place capping system

Our CCP-131 innovative and highly efficient continuous motion, pick and place capping system has been specifically designed for easy operation and quick change-over for different capping specifications and requirements. The CCP-131 Continuous Pick and Place Capping Machine’s new continuous style pick & placing function is driven by triple servo motors and ensures product security and closure consistency, every time.

Most of the machines parameters can be adjusted via the integrated touchscreen HMI, avoiding the need for complicated mechanical adjustments. The CP-131 Continuous Pick and Place Capping Machine is the perfect solution for varying bottle and cap styles.