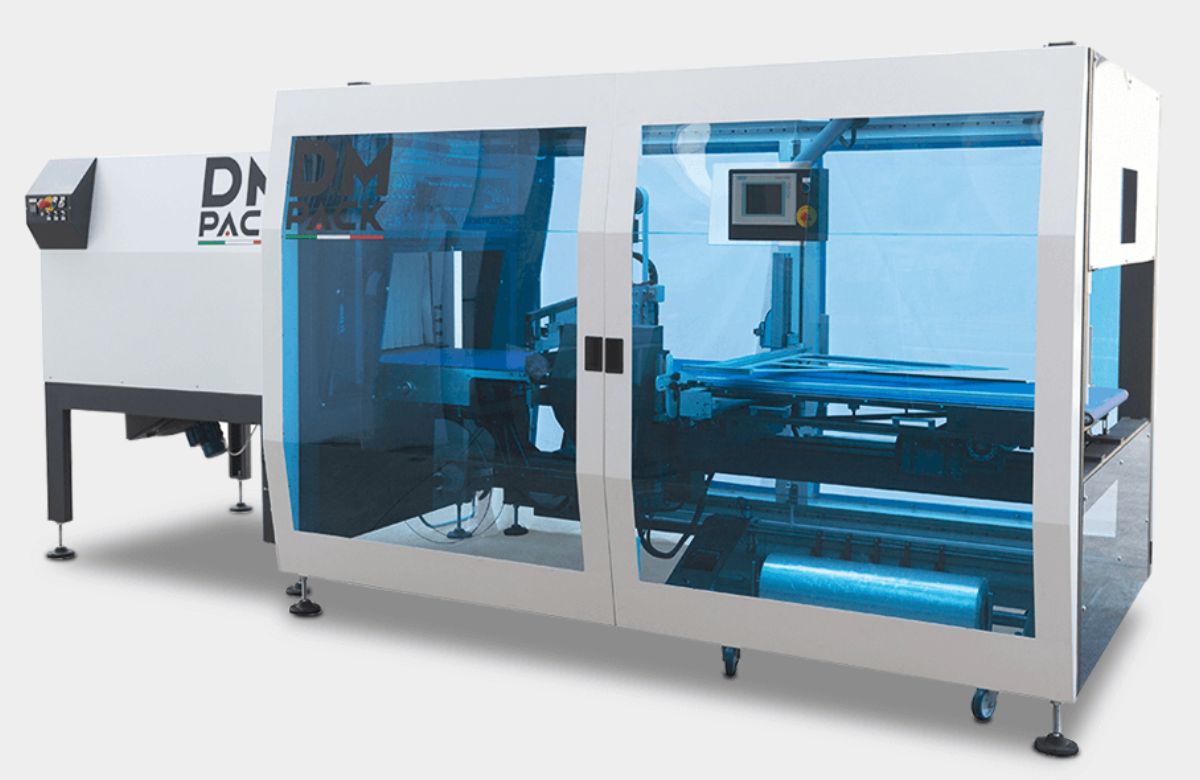

We offer a range of shrink wrapping machines. They are great for packaging all sorts of shapes and sizes of containers, and not only can they contain and protect your products during transit, they can make your products look more professional and attractive to customers.

Plus, it’s kind of fun to watch the plastic shrink and conform to the shape of whatever you’re wrapping. So, whether you’re running a business or you just love playing with plastic, a shrink wrap machine is definitely a cool tool to have around.