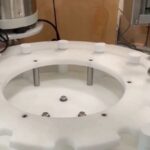

CP-101 Automatic Capping Machine

Sort, feed and close caps with speed and accuracy

Our CP-101 automatic capping machine is able to accommodate a large number of caps and ensures product security and closure consistency, every time. Both the high-accuracy capping head and star wheel assembly are controlled by our servo system.

Most parameters can be adjusted through the touchscreen interface without complicated mechanical adjustment. The cap sorting, feeding, placing, closing and bottle movement can all be easily adjusted to ensure the correct torque value is applied.

This environmentally friendly machine incorporates low energy consumption and requires just 1.5 kW. It also has a specially designed liquid drain outlet for easy cleaning after production.