The History of Production Lines 12th Century – Present

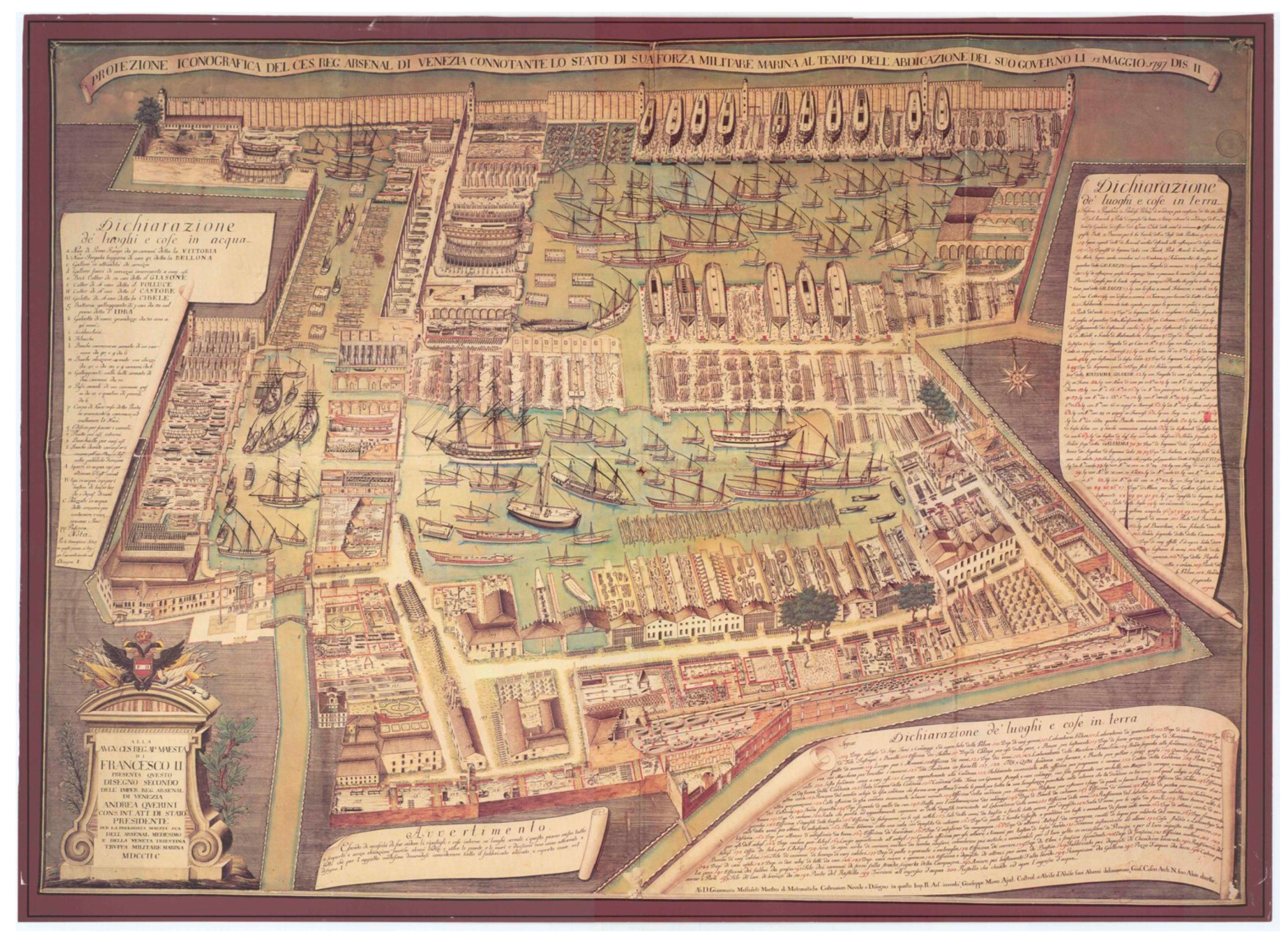

As early as the 1100s, in Venice, Italy, production lines were used to manufacture ships. As the ships sailed down a slow-moving river, different parts would be fitted at different stops. This is the earliest recorded example of an assembly or production line.

The Venetian Arsenal [Source: www.mdpi.com]

To quote Monty Python, “What did the Venetians ever do for us?” Well, they’re responsible for giving Advanced Dynamics employees a purpose (and job)!

Standardised Production in 1700s

Universal and standardised parts are common these days. It wasn’t until French gunsmith, Honoré LeBlanc, promoted the idea of using standardised parts in the firearms industry that they were introduced into production.

Essentially, this meant that weapons could be fixed easier than before. Prior to this, weapons would each be made by hand and so difficult to fix. There was no ‘replace this part with this spare and it will work again’. This would’ve led to quicker repairs and less wastage, but it just didn’t catch on with other manufacturers.

Samuel Bentham, European Naval engineer, had the similar idea of using uniform parts in the production of ship equipment, but again, it didn’t really catch-on.

Samuel Bentham [Source: en.wikipedia.org]

Interchangeable Parts in 1750s

In around 1750, the Industrial Revolution started, and our ancestors were intelligent enough to work smarter, not harder. They began to use machines instead of humans to do difficult, repetitive, and near impossible (for humans) tasks.

An innovation designed by Eli Whitney, American Inventor, transformed the way American businesses and organisations manufactured products. That innovation was interchangeable parts.

Eli Whitney [Source: Eli Whitney / Charles Bird King / 1821 / Private Collection / Via npg.si.edu]

Despite the idea of standardised production failing in Europe, Eli’s innovation proved to be a success out in the States.

Whitney was able to speed up production, with a large unskilled workforce, producing high-quality identical gun parts at a low cost. Again, this meant that repairs were now possible, faster and cheaper.

Production Lines Patented in 1900s

In 1901, vehicle manufacturer, Ransom Olds, patented the first ever modern production line.

Ransom Olds [Source: en.wikipedia.org]

Olds moved to this method of manufacturing so that his company, Oldsmobile, could increase their output by 500% in the first year. A true example of how automation can empower a business.

Oldsmobile were originally able to produce three to four of their Curved Dash models each day, and this was accelerated to twenty by using Olds’ ideas.

This car was the first to be manufactured in large quantities, and with a low cost and efficient assembly – other car manufacturers started to take notice.

In fact, Henry Ford, founder of the Ford Motor Company, took notice of this production model and implemented his own version.

Henry Ford Pioneers Production in 1940s

Henry Ford didn’t just take the idea and run with it – he elevated it to another level.

Ford built giant conveyor belts that moved WIP items around the factory. This was achieved by using rope and toggles to move the chassis of each car around the factory floor, while worked assembled the different parts in their respective areas.

:max_bytes(150000):strip_icc()/fordassemblyline-56b6b8355f9b5829f83428af.jpg)

The Ford Motor Company factory [Source: blog.unex.com]

This meant that one Ford Model T could be produced every hour and a half, totaling almost two million in a year.

Robots in 1960s

Engineers around the globe started to experiment with robotics in automation, to accelerate efficiency in industry and manufacturing.

Automotive manufacturer, General Motors, installed a robotic arm on their assembly line in 1961.

[Source: upcommons.upc.edu]

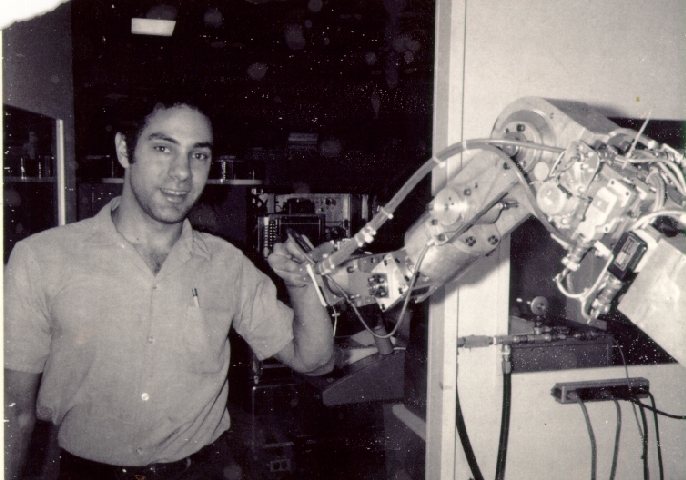

Stanford engineer, Victor Scheinman, again elevated this (no pun intended) in 1969 when he produced a 6-axis robotic arm dubbed the ‘Stanford Arm’, that had the ability to repeatedly move and assemble parts.

Vic Scheinman & the ‘Stanford Arm’ [Source: robohub.org]

This was one of the standout innovations and is still, in some forms, used today!

Production in 21st Century

Nowadays, Advanced Dynamics are expanding the ways that businesses can leverage automation in production.

Not only can we just support businesses that want to fill, package, cap, sort, or wrap, but we provide ongoing maintenance support and repairs with standardised parts (thanks again Eli Whitney).

We aspire to be the most proactive and supportive business in the packaging industry. In fact, it is our mission.

Want to accelerate your production and grow your business?