Whisky Bottling: Production Line Guide

Whisky has long been a symbol of craftsmanship in the UK and Ireland, from the peaty single malts of Islay to smooth Irish blends. Each bottle carries years of dedication, heritage, and skill — and when it comes to bottling, that same level of care is essential.

The bottling process is where the whisky’s journey meets the customer. Every step — from filling to labelling — must protect its character, meet regulatory standards, and present it in a way that reflects its premium nature.

The Unique Challenges of Whisky Bottling

Alcohol Content

Many whiskies, especially cask-strength varieties, have an alcohol content above 45% ABV.

Preserving Flavour & Aroma

Unlike carbonated drinks or lower ABV spirits, whisky benefits from a gentle filling process to minimise oxidation and maintain its distinctive nose and taste profile.

Flexible Bottle Handling

From miniatures for gifting to 70 cl bottles for retail and bespoke formats for limited editions, whisky producers need machinery that can adapt quickly between bottle shapes and sizes.

Premium Presentation

Whisky packaging often involves multiple labels — front, back, and neck — plus decorative features like foil seals or shrink sleeves. Precision is key to achieve a high-end finish.

The Whisky Bottling Process

While every distillery has its own approach, whisky bottling typically involves:

1. Bottle Sorting & Feeding

Ensuring bottles are sorted and oriented.

2. Rinsing & Priming

Ensuring whisky bottles are clean and primed ready for filling.

3. Filling

Using volumetric or vacuum filling to accurately measure and gently dispense the spirit.

4. Capping or Corking

Securing closures that complement the brand’s style, from traditional corks to modern screw caps.

5. Labelling

Applying multiple labels with precision, including any tax stamps or tamper-evident features.

6. Secondary Packaging

Sleeving, cartoning, and palletising ready for distribution.

Machinery for Whisky Bottling

Advanced Dynamics supplies a full range of bottling machinery designed to meet the demands of whisky production in the UK and Ireland. Each system can be configured to your exact requirements — whether you’re producing small-batch releases or running high-volume lines.

Bottle Unscramblers & Feeders

Bottle sorting solutions automatically orient and feed bottles into the line, ensuring a smooth start to the process. For whisky, this is particularly important when switching between miniatures, standard 70 cl bottles, or limited-edition formats.

See how whisky bottles are fed into a uniform line with this whisky bottle feeding conveyor:

Bottle Rinsing Machines

Bottle rinsing machines for whisky ensure each bottle is cleaned and free from dust or debris before filling, protecting product quality and taste. They can use air, water, or a filtered alcohol rinse, with gentle handling to avoid damaging premium glassware or decorative finishes.

Explore our BR-100 bottle rinsing machine for whisky production by clicking here.

Filling Machines

Volumetric and vacuum fillers deliver precise, consistent fills while handling high-ABV spirits with care. Vacuum filling helps reduce foaming and oxidation, preserving the whisky’s aroma and flavour.

See how whisky bottles are filled with this fully automatic quad-head whisky filling machine:

You can find out more about the FL-14 fully automatic filling machine for whisky by clicking here.

Capping & Corking Equipment

Our closure systems can handle everything from T-corks for premium single malts to screw caps for blended whiskies, maintaining tight seals and an attractive presentation. Quick-change tooling means you can switch between closure types with minimal downtime.

See an whisky T-cork capping machine in action here:

You can find out more about the CP-10D t-cork capping machine for whisky by clicking here.

Or see a Pick and Place Screw Cap Capping Machine for whisky in action here:

You can find out more about the CP-10D screw cap capping machine for whisky products by clicking here.

Labelling Systems

Whisky often requires multiple labels — front, back, and neck — as well as tax stamps or decorative elements. Our labelling machines offer pinpoint accuracy and can handle complex label combinations without sacrificing speed.

You can see whisky bottles being labelled by this automated wraparound labeller here:

Find out more about the PL-501 wraparound labelling machine for whisky bottles by clicking here.

Shrink Sleeving Machines

Shrink sleeve applicators provide tamper-evident seals or full decorative sleeves, helping protect the product and enhance shelf appeal. This is particularly effective for special releases or export markets where additional security is required.

You can see whisky bottles being sleeved by this high performance automated sleeving machine here:

The SL-301 shrink sleeving machine for whisky bottles is flexible in its operation, offering a variety of options with speeds up to 300 bpm. You can find out more about this whisky bottle sleeving machine here.

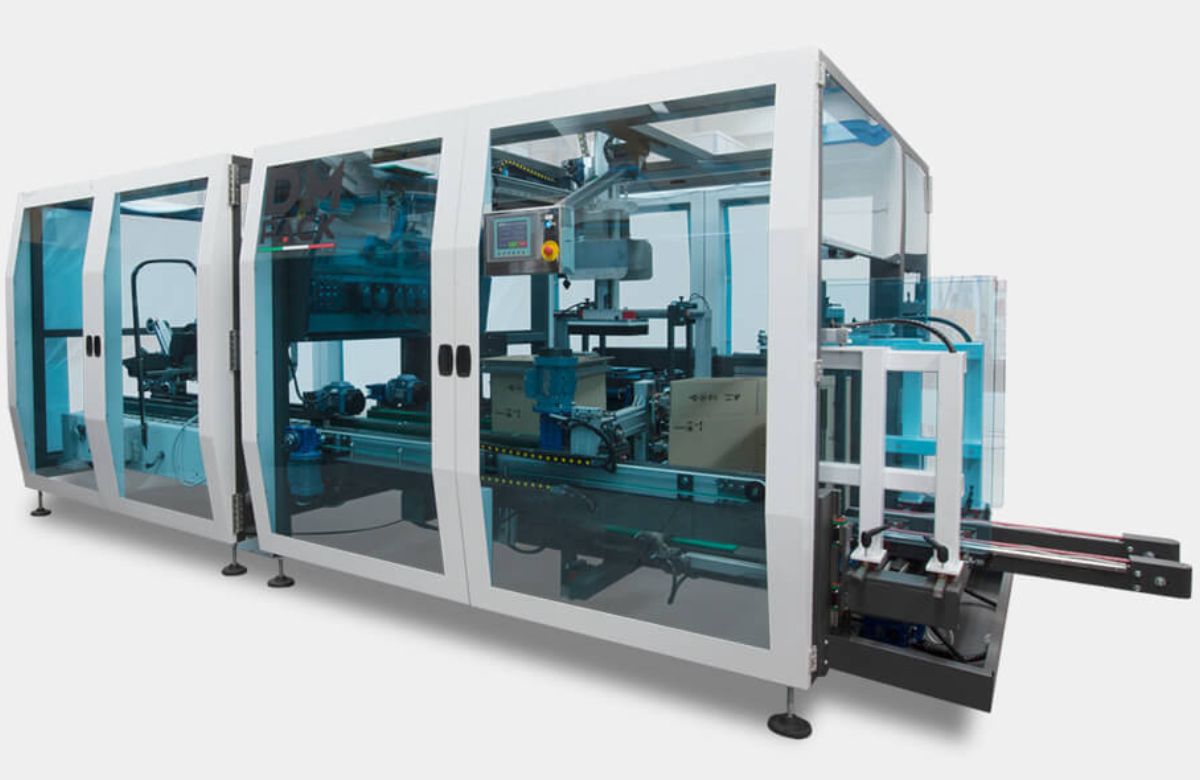

End-of-Line Solutions

From cartoners and case packers to palletising systems, our end-of-line equipment ensures bottles are securely packed for transport, protecting the premium product until it reaches the customer.

Shrink Wrapping Machines

Shrink wrapping machines bundle multiple whisky bottles together, offering protection during transportation and storage. This step is essential for maintaining product integrity and facilitating efficient logistics. The importance of shrink wrapping machines lies in their ability to create durable and secure packaging that can withstand handling and environmental factors. By tightly wrapping bottles, these machines prevent movement and potential breakage, ensuring that products arrive at their destination in perfect condition.

Our automatic shrink wrap machines can cater for a variety of products including whisky bottles. To discover more about our shrink wrapping machines for whisky bottles, click here.

Cartoning Machines

Cartoning machines package whisky bottles into cartons, making them ready for distribution. This step involves precise handling and placement to avoid damage. Cartoning machines are crucial for the efficient and safe packaging of whisky bottles, ensuring that they are securely enclosed and protected. The importance of these machines is highlighted in their ability to handle various carton sizes and configurations, providing flexibility for different packaging needs. By automating the cartoning process, businesses can reduce manual labour and increase throughput during whisky production.

Palletising Systems

Palletising systems stack and organise cartons of whisky bottles onto pallets for efficient storage and transportation. Automated palletising systems enhance productivity and reduce manual labour, ensuring that products are prepared for shipment quickly and accurately. The importance of palletising systems is seen in their ability to optimise space usage and ensure stability during transport. By automating this process, businesses can improve logistics efficiency, reduce the risk of product damage, and streamline their supply chain operations.

Preserving Heritage with Precision

Whisky is more than a drink – it’s a story in a bottle. By combining the artistry of distilling with the reliability of modern bottling technology, producers in the UK and Ireland can ensure every release reaches customers in perfect condition, looking as exceptional as it tastes.

If you’re exploring ways to improve efficiency, flexibility, or compliance in your whisky bottling process, Advanced Dynamics can help you create a tailored packaging solution that meets your production goals while protecting the spirit of your product. No pun intended. Get in touch today to find out how we can help you set up your whisky bottling line.