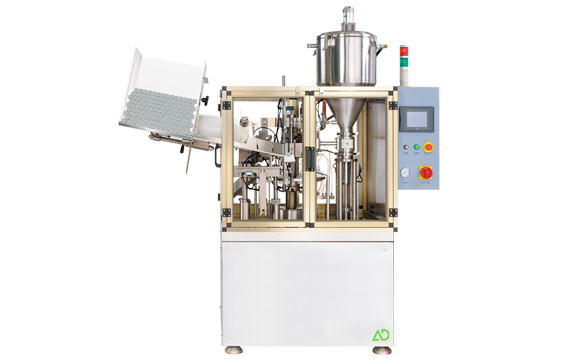

FL-300 Fully Automatic Tube Filler & Sealer

High Speed Tube Filling

The FL-300 is a flexible, fully automatic tube filling and sealing machine that is best suited for handling metal, plastic, aluminium and laminate tubes. This machine is ideal for filling pastes, creams, lotions, gels and various other thick and semi-viscous products.

The FL-300 is a highly efficient machine that enables easy operation and fast change-over times for different product specifications and requirements. Offering exceptional flexibility, the machine can adapt to a range of tube sizes, materials and filling volumes.

The anti-drip design features a “no-tube, no-fill” system that prevents the filler from dispensing the product when no tube is detected, and the production pre-set function enables the FL-300 to automatically stop once the pre-set quantity of products has been filled.

It’s fully enclosed design not only protects the filler and product from any interference that could cause potential harm, but also protects the operator from the fast moving parts.

The machine comes with an intelligent temperature control and cooling system which makes operation easy and sealing reliable, and a high quality touch screen & PLC control system to deliver a convenient, visual and reliable non-touch operation.

The strong and steady frame is made from durable 304 stainless steel and anodised aluminium. Any parts in contact with the materials being filled are made from 316 stainless steel. This durability translates in to an easy-to-maintain machine with a long life.

Automatic Process From Tube Loading, Positioning and Filling to Heating and Sealing of the Finished Product

Anti-Drip Design Features a “No-Tube, No-Fill” System

High Quality Touch Screen Control System

Intelligent Temperature Control and Cooling System

Suitable for Multiple Kinds of Soft Tubes for Filling

Can Adapt to a Range of Tube Sizes, Materials and Filling Volumes

Parts in Contact With Materials Made of 316 Stainless Steel

Production Pre-Set Function

Overload Protection - Filling Is Carried Out Only When Tubes Are Fed

Low Energy Consumption With Generous Output Speeds

Full Spares and Service Support From Our Bradford Based Team

Technical Specification

Not sure what you need? Let’s talk it through.

We believe that to provide the best solution to your requirements, we must first listen. Either by phone or face to face, we aspire to make our first conversation the beginning of a long term, mutually beneficial partnership.